Laser Solutions for Device Cutting from Tubes and Flat Stock

Today, nearly all precision laser cutting of metals and non-metals is performed with tools equipped with either fiber lasers or ultrashort pulse (USP) lasers, or sometimes both. In this article, we explain the different advantages of both laser types and look at how two manufacturers are using these lasers. NPX Medical (Plymouth, MN) is a contract specialty machining company for a diverse variety of devices and deployment tools such as stents, implants, and flex tubes, using a machine incorporating a fiber laser. Motion Dynamics manufactures subassemblies such as “pull-wire” assemblies mostly for use in neurology, utilizing a machine incorporating a USP femtosecond laser as well as one of the latest hybrid systems that includes both a femtosecond laser and a fiber laser, for maximum flexibility and versatility.

Ultrashort-Pulse Laser Versus Fiber Lasers

For many years, most laser micromachining was performed using solid-state nanosecond lasers called DPSS lasers. But this situation is now completely changed due to the development of two quite different, and thus complementary, laser types. The fiber laser that was originally developed for telecom has matured to become a workhorse materials-processing laser in many industries, usually at near-infrared wavelengths. The reason for its success is its simple architecture and straightforward power scalability. This results in lasers that are compact, highly reliable, and easy-to-integrate into specialized machines and usually offer lower cost of ownership than older laser types. And importantly for micromachining, the output beam can be focused down to a small, clean spot just a few microns in diameter, so they are well-suited to high-resolution cutting, welding, and drilling. Their output is also highly flexible and controllable, with pulsing rates all the way from single shot to 170 kHz. Together with the scalable power, this supports fast cutting and drilling.

However, the one potential drawback for fiber lasers in micromachining is with the processing of small features and/or thin, delicate parts. The long (e.g., 50 µs) pulse duration can cause a small amount of heat-affected zone (HAZ) such as recast material and minor edge roughness, which may require some post-processing. Fortunately, the new type of laser—the ultrashort-pulse (USP) laser with femtosecond output pulses—eliminates the HAZ issue.

With USP lasers, most of the extra heat associated with the cutting or drilling process is carried away in the ejected debris, before it has time to spread into the surrounding material. USP lasers with picosecond output have long been used in micromachining applications involving plastics, semiconductors, ceramics, and some metals (a picosecond = 10-12 seconds). But for metal devices with struts as small as a human hair, the high thermal conductivity of the metal and the tiny dimensions mean that picosecond lasers did not always deliver the improved results that would justify the increased cost of early USP lasers. This situation has now changed with the advent of industrial-grade femtosecond lasers (a femtosecond = 10-15 seconds). An example is the Monaco series of lasers from Coherent Inc. Like fiber lasers, their output is in the near infrared, meaning they can cut or drill all the metals used in medical devices including stainless steel, platinum, gold, magnesium, cobalt chrome, titanium, etc., as well as non-metals. And while the combination of short pulse duration and low pulse energy prevents thermal damage (HAZ), the high (MHz) repetition rate ensures cost-effective throughput speeds for many high-value medical devices.

Specialized Laser-Cutting Machines

Of course, virtually no one in our industry needs just a laser; rather, they need a laser-based machine, and there are now a number of specialty machines optimized for medical device cutting and drilling. An example is the StarCut Tube series from Coherent, which is available with a fiber laser, a femtosecond laser, or as a hybrid version that includes both laser types.

What do we mean by specialized for medical devices? Most of these devices are created in limited batch quantities often based on customized designs. Flexibility and ease of use therefore are critical considerations. And while many devices are created from tube blanks, a few components must be precision machined from flat stock; the same machine must handle both in order to maximize its value. These needs are typically met by providing multiple axes of CNC-controlled (xyz and rotary) motion together with a user-friendly HMI for simple programing and control. In the case of the StarCut Tube, a new tube-loading module option with a side-loading magazine (called StarFeed) for tubes up to 3 m in length and a sorter for the cut products allow for fully automated hands-off production.

Process flexibility is further enhanced in these machines by supporting both wet and dry cutting as well as an easily adjustable delivery nozzle for processes needing an assist gas. Spatial resolution is also particularly important for machining very small parts, which means thermomechanical stability to eliminate the effects of vibrations often encountered in machine shops. This need is met in the StarCut Tube series by building the entire cutting platform out of massive granite elements.

NPX Medical – Cutting Diverse Components

NPX Medical is a fairly new contract manufacturer that provides design, engineering, and precision laser-cutting services to medical device manufacturers. Founded in 2019, the company has rapidly established a reputation in the industry for quality products and fast response supporting a diverse range of devices, including stents, implants, valve scaffolds, and flex delivery tubes for a similarly diverse range of surgical interventions including neurovascular, cardiac, renal, spinal, orthopedics, gynecology, and gastrointestinal procedures. Its main laser-cutting machine is the StarCut Tube 2+2 equipped with a StarFiber 320FC with 200 watts of average power. Mike Brenzel, one of the NPX founders, explained that “the founders brought years of experience in medical device design and manufacturing—over 90 years in total—with previous experience with similar StarCut machines using fiber lasers. A lot of our work involves nitinol cutting, and we already knew that a fiber laser would deliver the speed and quality we needed. We need speed for thick-walled tubes and devices such as heart valves where a USP laser might be too slow for our needs. In addition to large production orders—we specialize in producing parts in small quantities—between just 5 and 150 units—and we aim to do a complete turnaround on these small batches in just a few days including design, programing, cutting, forming, post processing, and inspection, in contrast to larger companies that might require several weeks after order placement.” In addition to mentioning speed, Brenzel also cited the machine’s reliability as a major advantage with not a single service call required in the past 18 months of near-continuous operation.

Figure 2. NPX offers a variety of post-processing options. The material shown here is T316 stainless steel with a O.D. of 5 mm and a wall thickness of 0.254 mm. The left side part is as-cut/micro-blasted, and the right side part is electropolished.

Figure 2. NPX offers a variety of post-processing options. The material shown here is T316 stainless steel with a O.D. of 5 mm and a wall thickness of 0.254 mm. The left side part is as-cut/micro-blasted, and the right side part is electropolished.

In addition to nitinol parts, the company also works extensively with cobalt chrome, tantalum, titanium, and several types of medical stainless steels. Jeff Hansen, laser processing manager, explained that “machine flexibility is another important asset [that] allows us to support a really diverse range of material cutting including both tubes and flat stock. We can focus the beam down to a 20 microns spot, which is great for thinner tubes. Some of these tubes have an internal diameter of only 0.012 in. and the high ratio of peak power to average power of the latest fiber lasers maximizes our cutting speeds while still delivering the requested edge quality. And we definitely need the speed for larger products [that] might have outer diameters up to 1 inch.”

As well as precision cutting and fast response, NPX also provides a full range of post-processing techniques, plus comprehensive design services that draw on their considerable experience in the industry. These techniques include electropolishing, grit blasting, pickling, laser welding, heat setting, forming, passivating, Af temperature testing, and fatigue testing, all which are key to nitinol device manufacturing. Brenzel said the use of post processing to manipulate edge finish “often depends on whether we’re talking about high-fatigue or low-fatigue applications. For example, a high-fatigue part like a heart valve might be expected to flex a billion times over its lifetime, and it is very important to use grit blasting to increase the radius on all the edges as a step in post processing. But a low-fatigue part like a delivery system or guide wire typically doesn’t require extensive post-processing.” In terms of design expertise, Brenzel explained that up to three-quarters of their customers now use their design services in addition to drawing on NPX’s help and skill in getting FDA approval. The company is quite adept at turning “napkin sketch” concepts into final form products in short order.

Motion Dynamics – Creating Sub-Assemblies for Neurological Procedures

Motion Dynamics (Fruitport, MI) is a manufacturer specializing in custom micro springs, medical coils, and wire components with a mission of solving their customers’ problems in the shortest possible time, no matter how complex or seemingly impossible. In medical devices, it offers a major emphasis on complex assemblies for neurovascular procedures, encompassing the design, production, and assembly of high-quality wire components for applications such as steerable catheter devices including “pull-wire” assemblies.

As already noted, the choice of fiber or USP laser is a question of both engineering preference and the type of devices and processes being supported. Chris Witham, president of Motion Dynamics, explained that “the company is based on a highly focused business model in neurovascular products, where we can offer differentiated results in terms of design, execution, and service. We use laser cutting solely to generate the components that we use in house to create the high-value, ‘difficult’ assemblies that have become our specialty and our reputation; we don’t offer laser cutting as a contract service. We have found that most of the laser cutting we perform is best done with a USP laser and have had a StarCut Tube equipped with one of these lasers for several years. Because of the strong demand for our products, we run two 8-hour shifts/days and sometimes three, and in 2019 we needed to acquire another StarCut Tube to support this growth. But this time we decided on one of the new hybrid models with a femtosecond USP laser as well as a fiber laser. We also paired this with a StarFeed loader/unloader so that we can fully automate the cutting—the operator simply loads the feeder with blank tubes and initiates the software operating routine for that product.”

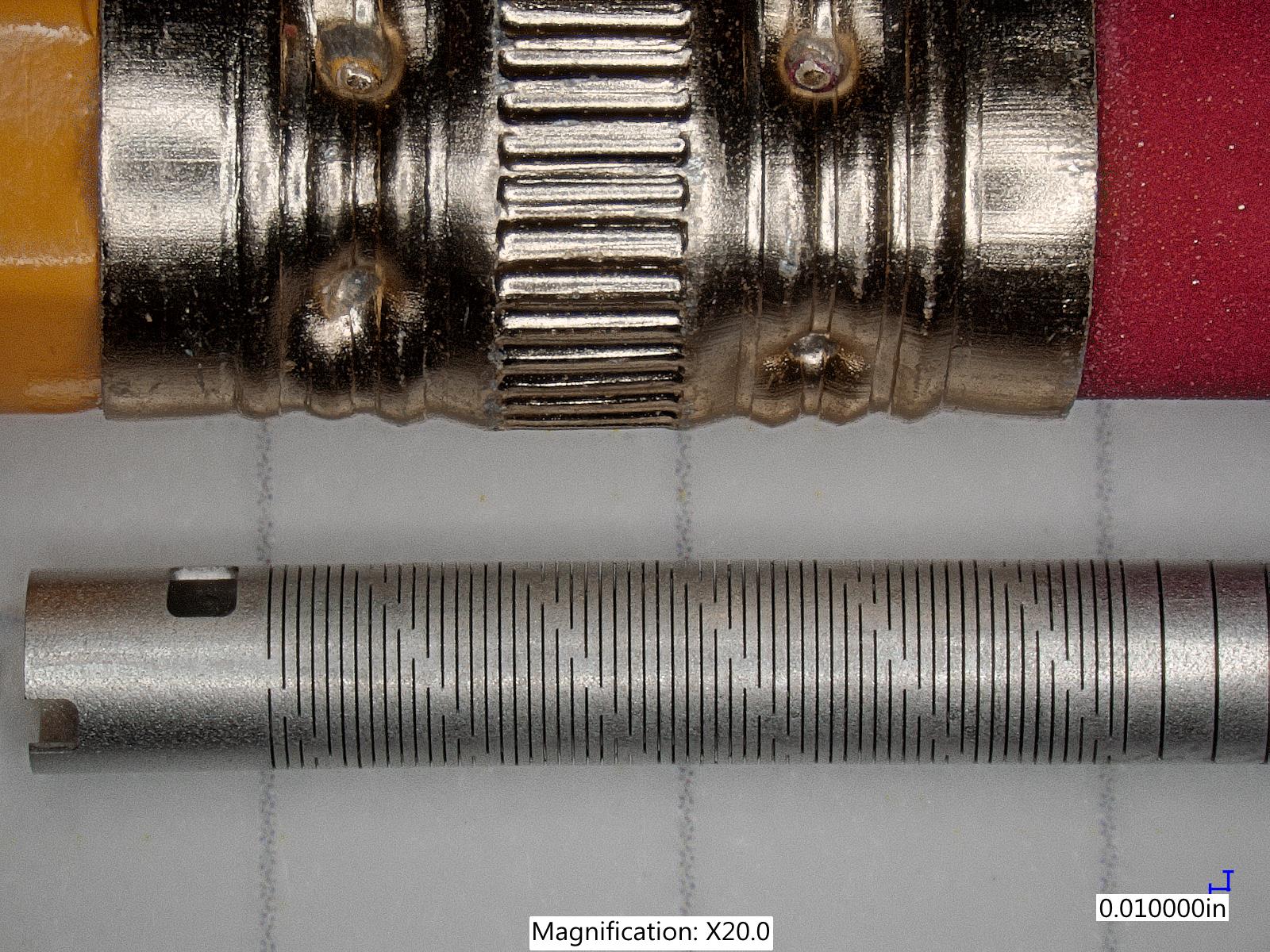

Figure 3. This flexible stainless-steel delivery tube (shown next to a pencil eraser) has been cut with a Monaco femtosecond laser.

Figure 3. This flexible stainless-steel delivery tube (shown next to a pencil eraser) has been cut with a Monaco femtosecond laser.

Witham adds that although they occasionally use the machine for flat cutting, over 95% of the time it is used for creating or modifying cylindrical products for their steerable catheter assemblies, namely hypo tubes, coils, and spirals, including cutting shaped tips, and cutting holes. These assemblies are ultimately used for procedures such as aneurism repair and blood clot removal. This requires using the laser cutter on a full range of metals including stainless steel, pure gold, platinum, and nitinol.

Figure 4. Motion Dynamics also makes extensive use of laser welding. Above, the coil has been welded to a laser-cut tube.

Figure 4. Motion Dynamics also makes extensive use of laser welding. Above, the coil has been welded to a laser-cut tube.

What about the choice of lasers? Witham explains that superior edge quality and minimized kerf are critical in most of their components hence their original preference for a USP laser. In addition, there is no material the company uses that cannot yet be cut by one of these lasers, including the tiny gold components used as radio-opaque markers in some of their products. But he adds that the new hybrid option including both a fiber laser and a USP gives them more flexibility in optimizing the speed/edge quality question. “The fiber definitely delivers much higher speed without question,” he said. “But because of our particular application’s focus, this often means some type of post-processing such as chemical and ultrasonic cleaning or electro-polishing. So, having the hybrid machine allows us to choose which overall process— USP alone or fiber and post-process—is optimum for each component. And it is allowing us to explore the possibility of mixed processing of the same component, particularly where larger diameters and wall thicknesses are involved: namely fast cutting with the fiber laser followed by fine cutting with the femtosecond laser.” He expects that the USP laser will remain their first choice because although they encounter wall thickness ranging from 1-20 thou, the majority of their laser cutting involves stainless tubes with wall thicknesses between four and six thou.

Summary

In conclusion, laser cutting and drilling are critical processes used in the fabrication of all kinds of medical devices. Today, these processes are easier to use and deliver better results than ever before, thanks to advances in core laser technologies and highly optimized machines configured for the particular needs of this industry.